Home

About S P Engineering

At S P Engineering, we take pride in making a strong and lasting impression on our valued customers by delivering high-quality packaging machines. With a bold presence in the market, we specialize in manufacturing an exceptional range of machines designed to meet the evolving needs of industries such as pharmaceuticals, chemicals, food, and more.

Located in Dombivli, Maharashtra, India, our company offers a wide array of advanced packaging solutions, including Capping Machines, Carton Sealers, Granule Filling Machines, and other specialized equipment. We prioritize understanding the unique requirements of our clients to serve them with precision and care.

Our commitment extends beyond manufacturing—we keep our customers informed about new innovations and additions to our product line, ensuring they always have access to the latest technology. At S P Engineering, we deliver only those solutions that truly stand out and leave a lasting impression.

Products

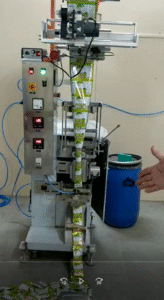

Automatic Powder Packaging Machine

Designed for efficient and accurate packaging of free-flowing powder, granules such as tea, coffee, sugar, seeds, and detergents, this FFS machine automates the entire process — from forming pouches to precise filling and sealing.

Highlights:

High-speed granular dosing system

Compatible with various pouch styles

Sturdy stainless-steel build for hygiene

PLC-based control with touchscreen interface

Low maintenance, high reliability

A perfect solution for granule packaging in the Pharma, food, agro, and chemical industries.

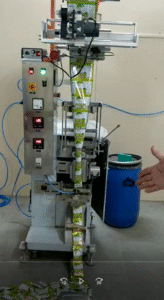

Automatic Liquid Packaging Machine

Our Automatic Liquid FFS Machine is a compact and high-performance solution designed to pack liquid and semi-liquid products with speed, accuracy, and hygiene. Ideal for industries like food & beverages, pharmaceuticals, and chemicals, this machine automates the pouch forming, filling, and sealing process with minimal human intervention.

Key Features:

✅ High-Speed Operation: Efficiently packs water, juices, milk, shampoo, oil, and other liquids.

✅ Leak-Proof Sealing: Ensures airtight, spill-free packaging using heat-sealing technology.

✅ Versatile Pouch Types: Supports center seal and three-side seal pouches.

✅ Hygienic SS Construction: Made of stainless steel for easy cleaning and compliance with food and pharma standards.

✅ Accurate Filling System: Uses piston or gravity-based filling (as per product type) for precise volume control

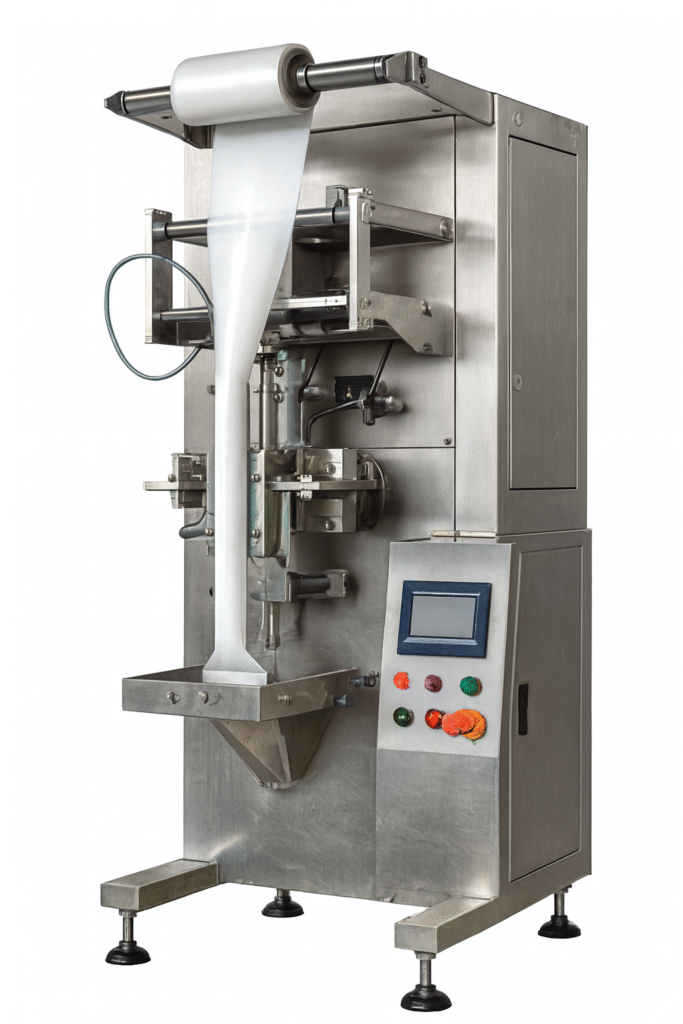

Form Fill & Seal Machine

Designed for efficient and accurate packaging of free-flowing powder, granules such as tea, coffee, sugar, seeds, and detergents, this FFS machine automates the entire process — from forming pouches to precise filling and sealing.

Highlights:

High-speed granular dosing system

Compatible with various pouch styles

Sturdy stainless-steel build for hygiene

PLC-based control with touchscreen interface

Low maintenance, high reliability

A perfect solution for granule packaging in the Pharma, food, agro, and chemical industries.

Horizontal Band Sealing Machine

Model | FR-900 |

Voltage | 110V/220V 50-60HZ |

Power | 500W |

Sealing speed | 0-12m/min |

Sealing width | 6-12mm |

Temperature range | 0-300℃ |

Max. conveyor loading | 3kgs |

Printing category | Steel wheel printing |

Weight | 19kg |

Machine size | 850X400X310mm |

Vaccum Packaging Machine

| Model No | DZ6002SB |

| Chamber Size(mm) | Double SS Hood |

| Voltage (V/HZ) | 230/50 |

| Vacuum Pump Power (W) | 1500 |

| Sealing Power (W) | 1000 |

| Sealing Width(MM) | 10 |

| Sealing Chamber | 2 |

| Chamber Size(MM) | 720X550X45 |

| Sealing Length | 600 |

| Vacuum Pump (M3/H) | 40 |

| Weight | 240 |

Handy Batch Coding Machine

Operation Linux, Quad 1.4GHz

Screen 4.3 Inches LCD Touch Display

Interface USB, Photoelectric Sensor

Battery DC14.8V, 2600mAh

Adapte AC100-240V, DC16.8V/2A

Size 23.9*12.3*11.8cm, 1.12KG

Texture Metal + ABS

Working

Conditions

0-45℃ Humidity 40-60% RH

DPI 600

Language English, Chinese, Arabic, German, Farsi

Print Height 2-12.7mm, support 1-7 lines

Print Distance 2- 5mm, from nozzle to object

Ink Type Solvent ink, Water ink

Ink Color Black, White, Red, Yellow, Blue, Green

Print Materials Porous & Non-porous materials, Plastic, Carton, Metal, Wood, Ceramic

Print Contents Text, Time, Serial number, Logo, QR Code(Variable), Barcode, DM Code